特点:高强度、高模量、低成本

工艺:快速拉挤成型

概述:玻纤拉挤板利用拉挤工艺的稳定性以及高玻纤含量的特性,在保证的质量稳定性的同时,将玻纤性能发挥到极致;为风电叶片的生产,提供了全新的高性能低成本的解决方案。风渡充分利用重庆国际复合材料股份有限公司在风电行业的玻纤技术,将TM+、TMII、TMIII等不同性能的玻纤开发成不同性能的玻纤拉挤板材,满足不同的客户需求。

优点:产品具有优异的力学性能和工艺性能,生产效率高,稳定性好,可靠度高。能减轻叶片重量,降低成本,适应风电平价时代。

亮点:已实现免脱模布工艺、低成本

Features: High strength, high modulus, Low cost

Process: Pultrusion

Overview: Leveraging the stability of the pultrusion process and the high glass fiber content, our glass fiber pultrusion profiles maximize the performance of glass fiber while ensuring consistent quality. This provides a new, high-performance, low-cost solution for wind turbine bladeproduction.

Fengdu fully utilizes Chongqing Polycomp International Corporation.'s glass fiber technology in the wind energy sector to develop glass fiber pultrusion profiles with different properties, such as TM+ glass, TMII glass, and TMIII glass, to meet the diverse needs of our customers.

Advantages: The products exhibit excellent mechanical and processing performance, high production efficiency, good stability, and high reliability. They help reduce blade weight, lower costs, and adapt to the parity era of wind power.

Highlights:Achieved de-peel ply process and low cost.

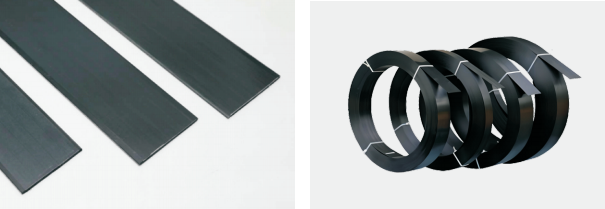

特点:高强度、高模量、低成本

工艺:快速拉挤成型

概述:碳纤维拉挤板利用拉挤技术,充分发货碳纤维的优势,生产出超高模量的碳纤维拉挤板,为未来大叶型叶片生产,提供了材料支撑。风渡新材将玻纤拉挤板丰富的生产与质量控制技术,延伸至碳板生产,已与多家碳纤维供应商建立了战略合作关系。在丰富的玻纤拉挤工艺经验基础上,风渡新材不断优化工艺,确保碳纤维的充分浸润以及碳板的直线度得到良好控制,实现了碳板的连续、稳定生产。

优点:产品具有优异的力学性能和工艺性能、生产效率高、稳定性好、可靠度高,能减轻叶片重量,适用于大型海上叶片设计。

亮点:已实现免脱模布工艺、低成本。

Features: High strength, high modulus, Low cost

Process: Pultrusion

Overview: Through the pultrusion process, we capitalize on the advantages of carbon fiber to produce ultra-high modulus carbon fiber pultrusion profiles, providing material support for the production of future large-scale wind turbine blades.

Fengdu extends its rich production and quality control techniques from glass fiber pultrusion profiles to carbon fiber profiles. We have established strategic partnerships with multiple carbon fiber suppliers. Building on our extensive experience in glass fiber pultrusion profiles, Fengdu continuously optimizes the process to ensure full impregnation of carbon fiber and proper straightness of the carbon profiles, achieving continuous and stable production.

Advantages: The products boast excellent mechanical and process performance, high production efficiency,good stability, and high reliability, which can reduce the weight of blades, making them suitablefor large offshore blade designs.

Highlights:Achieved de-peel ply process and low cost.

特点:性价比高、可设计性强

工艺:快速拉挤成型、分层设计

概述:风渡新材的碳玻混拉挤板材通过混杂方式设计、改进拉挤工艺,将碳纤维的高强度与玻璃纤维的韧性巧妙结合,实现了性能与成本的最佳平衡。该产品不仅具有优异的机械性能和,还在重量和价格上比全玻板及全碳纤维产品更具竞争力。

优点:产品具有优异的力学性能,生产效率高,稳定性好,可靠度高,能够降低叶片生产成本,适用于更长叶片设计。

Features: High cost-effectiveness, strong design flexibility

Process: Pultrusion,layered design

Overview: Fengdu’ carbon-glass hybrid pultrusion profiles are designed through a hybrid approach,improving the pultrusion process to cleverly combine the high strength of carbon fibers with the toughness of glass fibers, achieving the optimal balance between performance and cost. This product not only has excellent mechanical properties but is also more competitive in weight and price compared to glassfiber or carbon fiber products.

Advantages: The product features excellent mechanical performance, high production efficiency, good stability, and high reliability, capable of reducing blade production costs and is suitable for longer blade designs.