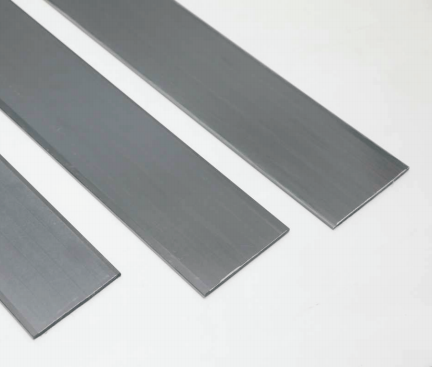

·高模量:碳纤维拉挤板模量可达到155GPa以上,提供极高的刚性和强度,满足高性能需求。

·低密度:碳纤维材料的低密度特性显著降低了叶片的整体质量,为大型叶片的设计和应用提供了新的方向和可能性。

·耐腐蚀,适应环境性强:面对各种严苛环境,碳纤维拉挤板表现出色的耐腐蚀性能。无论是在海洋或其他腐蚀性环境中,都能保持优 异表现。

·优异的耐疲劳性能:碳纤维材料具有出色的耐疲劳性能,显著延长了风电叶片使用寿命。无论是在高负荷还是反复使用的情况下,都 能保持稳定的性能。

· High Modulus:The modulus of carbon fiber pultrusion panels can reach over 155 GPa, providing exceptional rigidity and strength to meet high- performance demands.

· Low Density:The low density of carbon fiber materials significantly reduces the overall weight of the blades, offering new directions and possibilities for the design and application of large blades.

· Corrosion Resistance and Environmental Adaptability:Carbon fiber pultrusion panels demonstrate excellent corrosion resistance in various harsh environments. Whether in marine or other corrosive settings, they consistently deliver superior performance.

· Superior Fatigue Resistance:Carbon fiber materials exhibit outstanding fatigue resistance, significantly extending the lifespan of wind turbine blades. They maintainstable performance under both high loads and repetitive use.

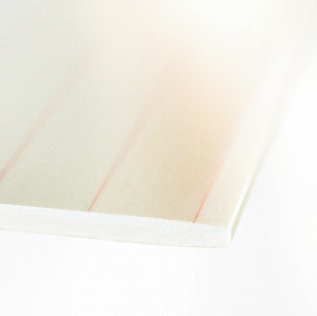

·高拉伸模量:具备60GPa、63GPa、65GPa、67GPa多种规格,拥有高比模量,提供卓越的结 构强度,满足不同应用需求,确保产品在各种条件下表现优异。

·优异的耐疲劳性能:使用寿命长,耐疲劳性能突出;耐腐蚀性强,能够适应多种环境条件。即 使在恶劣的气候和环境中,产品仍能保持高效稳定的性能,减少维护成本,提升可靠性。

·充分发挥玻璃纤维的性能优势:玻璃纤维的高强度和轻量化特点,使得叶片更轻便、更高效, 有助于提高整体系统的效率和经济性。扩大叶片设计范围,提高设计灵活性和创新性。

·降低综合成本:通过优化设计和材料选择,降低叶片综合成本。特别是在免脱模方面,提升安 全系数,显著提高生产效率。降低生产过程中的能源和材料消耗。

·稳定的力学性能:力学性能稳定,生产工艺优良,完全满足风电叶片的使用要求,确保产品质 量。

·大产量稳定供应:产量充足,保证持续稳定的供应,满足市场需求。

· High Tensile Modulus: Available in various specifications such as 60GPa, 63GPa, 65GPa, and 67GPa, it offers a high specific modulus, providing excellent structural strength to meet different application needs and ensuring outstanding performance under various conditions.

· Excellent Fatigue Resistance: With a long service life and exceptional fatigue resistance, it boasts strong corrosion resistance and can adapt to a variety of environmental conditions. Even in harsh climates and environments, the product maintains high efficiency and stability, reducing maintenance costs and enhancing reliability.

· Maximizing the Advantages of Glass Fiber: The high strength and lightweight characteristics of glass fiber make the blades lighter and more efficient, contributing to the overall system's efficiency and economy. It expands the blade design range, enhancing design flexibility and innovation.

· Reducing Overall Costs: By optimizing design and material selection, the overall cost of the blades is reduced. Particularly in terms of mold release-free processes, it improves safety factors and significantly enhances production efficiency, while reducing energy and material consumption during production.

· Stable Mechanical Properties: With stable mechanical properties and excellent production processes, it fully meets the usage requirements of wind turbine blades, ensuring product quality.

·Stable High Output Supply: With sufficient production capacity, it guarantees a continuous and stable supply to meet market demand.